Unique SF6 monitoring with reference gas comparison

The mechanical, self-acting device is based on the superior reference gas principle which does not need temperature compensation. It therefore not only covers all standard applications but also maintains highest accuracy over a very wide temperature range. It allows use of different gas mixtures or the application in montane altitudes or arctic temperatures down to minus 60 °C. It is equipped with high-performance micro switches and does not need any electrical energy supply. This precise and maintenance-free device is suited to demanding applications and is reliable over decades.

Advantages

Advantages

- No temperature compensation required due to superior reference chamber principle

- High resistance against vibration and shock

- No bouncing of electrical contacts

- Galvanically separated circuits

- No false alarms at low temperatures

- Maintenance-free, no recalibration of switchpoints

- Monitoring of other gases (e.g. CF4) possible

Operating Principle of the reference chamber

The gas density of SF6 compartments is compared via a bellows system with the gas density in a reference gas chamber in the monitor. If the density of the gas alters, the bellows system actuates one or more micro switches. If the gas temperature and therefore its pressure changes, the same pressure difference occurs also in the reference chamber. No false alarm is triggered due to temperature induced pressure changes. Up to four galvanically isolated micro switches actuate different alarm signals. An optional SF6 indicator provides visual inspection of the SF6 gas density as gas pressure at 20°C.

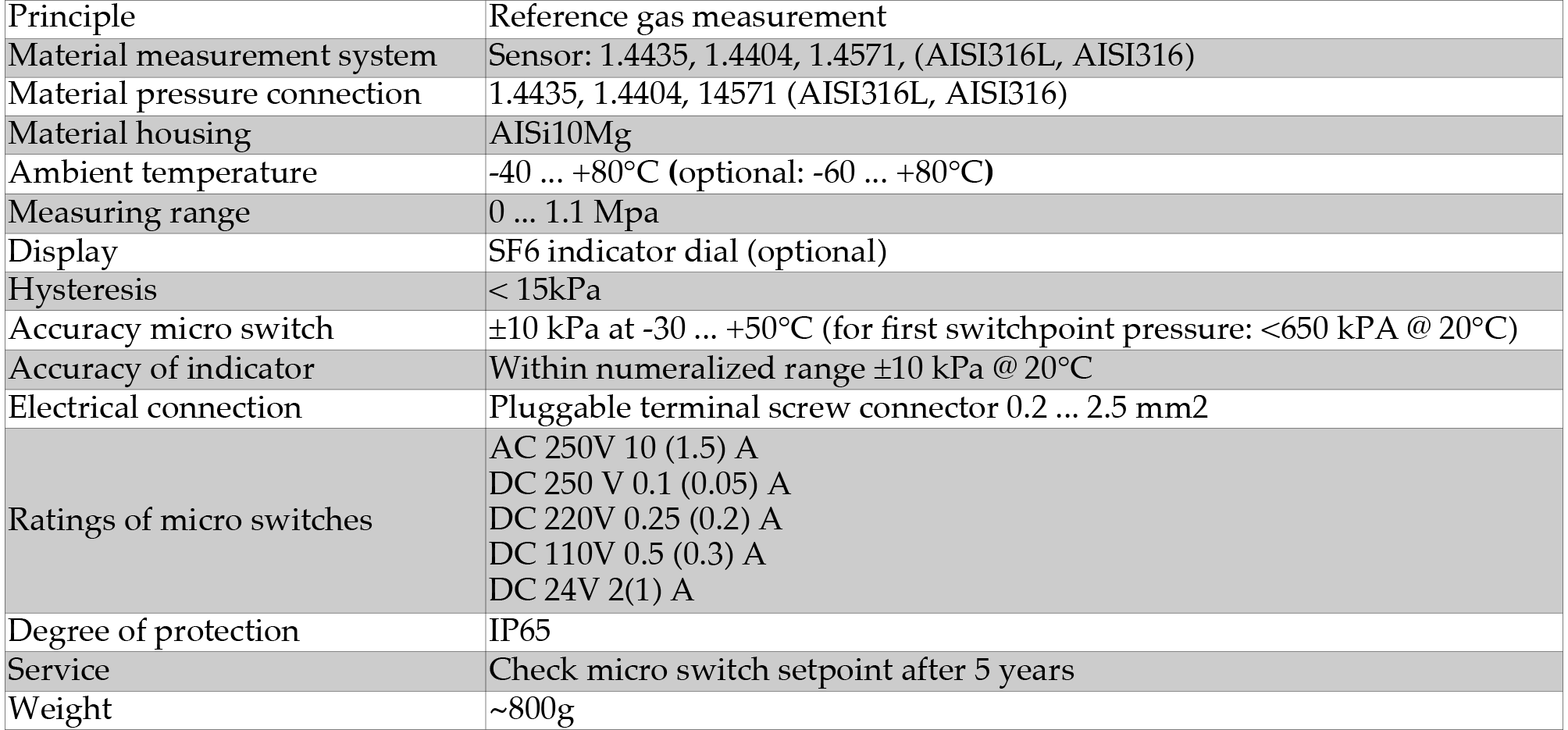

Technical Data