PTM

The PTM System (Pressure & Temperature Monitoring System) is an effective data logger with historical logging that excels in versatility and expandability depending on the end user’s requirement. The unit includes an industrial DAQ hardware for data acquisition which is connected via Ethernet through the RJ45 port on the hardware.

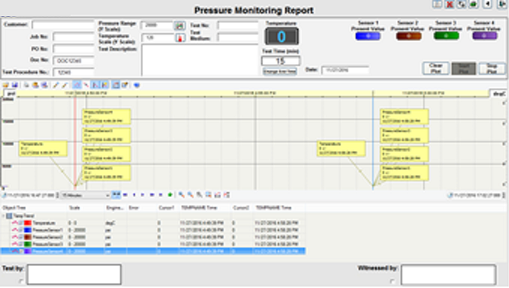

PTM Multichannel Measurement

Measures up to 4 analog inputs of passive pressure signals, 1 temperature input (thermocouple) and 1 bubble count signal (optional). The accuracy of the pressure signals are 16-bits, with ± 0.2% of FSR of the current at 25°C. The thermocouples supported by the system are Type J, K, S T, N and PT100. The sensors for bubble count are sink-type NPN sensors, although this is an optional feature of the PTM System.

Interactive and Effective Trending

Data is recorded into the computer hard-disk periodically. The end customer can retrieve historical data by selecting the testing date on the graph itself. The trend graph data can also be exported to CSV format.

The trend graph supports dual Y axes for pressure and temperature. There are also scrollable pens to display current values and time or previously logged values and time durations.

SQL Server Interface

SQL database for Customer, Sensor, Test Information. Ability to track & inform (T&I) ® customer of overdue sensor which require calibration.

User Friendly Interface for Easy Access

Should the end customer require both Process and Trend Graph screens visible at the same time, a dual screen option is available as well (end customer must have dual monitor support).

Report Generation

A PDF Report generation is available at any given time during the testing or after at the click of a button, and a screen capture of the current test cycle will be taken.

Digital Signature

The system also supports a WACOM digital signature pad input (to be provided by the end customer).